I have been making earthen ovens for over twenty years now. I made my first one in 1991 when I was working with architect Nader Khalili at CalEarth in the Mojave Desert. We were making a lot of adobe bricks at the time (friendly Persian-sized ones – 8â€x8â€x2â€) and also building domes of regular fired bricks. I’m not sure what got it into my brain to make an oven, probably an old picture of the ovens at Taos Pueblo. One day I made a round foundation of adobe bricks in a mud mortar bed right on the ground, then hammered a string in the middle and used that as a guide to lay up a dome of the half-sized bricks. I then covered that with a mud plaster. I don’t remember if I made a chimney hole or not. I made it big enough to fit a big roasting pan I found at the thrift store. I learned that this is good way to size your oven (and especially your door!). I also made a cob door reinforced with a piece of metal from an old patio chair. For my first thing I decided to make a turkey (!) I made a big fire of construction scraps, and when it burned down to coals I put the turkey in there. I put the adobe door against the opening and sealed it all up with mud. Ooooo. Now the wait… Four hours later, yum! Best turkey I ever had. Used it lots for a year, and learned to make bread in it. Bread is the true test of an earth oven baker, in my opinion. I burned my eyebrows a lot, and it was a pain to bend over, so I swore to make my next oven higher off the ground. I don’t have a photo, but I did do a self-portrait of myself with the oven. I’ll have to find that and scan and post it later.

I made my next oven when I was in South Africa in 1994. Why I was in South Africa is another (much longer) story, but the gist is that I was there designing and building at the Tlholego Development Project, a teacher training center for permaculture and natural building. I had designed a round outdoor sitting area of earthbags, and an earth oven just wanted to be there. The local ladies were already using the center of the sitting area to do open fire cooking with the cool three-legged cast iron pots they have down there. So, I taught some of the local guys how to make an oven based on my previous experience. A few years later I taught I course at Thlolego, and the course coincided with Thanksgiving. You know what comes next – in the effort to spread goodly American culture, we had Thanksgiving with all the trimmings, including… Turkey! We made six of them… a solar turkey, an earth oven one, and a couple in the regular oven in the farmhouse. They all turned out good. The photo shows my daughter Taya in the cooking area when we visited in 2004.

It was not until 1995 that I had the chance to meet another earth oven aficionado, and that was none other than the famous Kiko Denzer. We met at the 1995 Natural Building Colloquium at the Black Range Lodge in Kingston, and I learned from watching him make a beautiful oven with spread-wing bench. I had the chance to cook in that one a few times, when later I moved to the Lodge. I think I helped replaster it too. Another lesson: it is good to make a shelter over your oven.

It was not until 1995 that I had the chance to meet another earth oven aficionado, and that was none other than the famous Kiko Denzer. We met at the 1995 Natural Building Colloquium at the Black Range Lodge in Kingston, and I learned from watching him make a beautiful oven with spread-wing bench. I had the chance to cook in that one a few times, when later I moved to the Lodge. I think I helped replaster it too. Another lesson: it is good to make a shelter over your oven.

1n 1996 I was invited to Nova Scotia to teach a series of natural building courses with Bill and Athena Steen at the home of Kim Thompson, a local straw-bale and natural building advocate. My work there was to build the earth oven shelter of gravel bags, straw bales, earth plasters, and a roof of local timber for the “Quebec-style†earth oven built by Bill and Athena. This type of earth oven is unique because of its shape, and was different than others I had made. It had no chimney, was oval shaped, and had a relatively low roof. I real “aha†moment came when I saw that they used a sand form to create the support for the cob. This was dug out later. Brilliant. When I learned later about how well this oven fired, and even more, how it baked, I was sold on this shape. The basic lesson is that if an oven is too big, it does not bake efficiently, and that the interior shape of an oven (and the relationship to the shape/height of the door) is crucial to how well it works.

I first was exposed to a barrel oven when I spent several months at Gaia Ecovillage in Argentina in 1998. This was an intriguing device: a 55 gallon barrel held in place by brick ends with a brick vault built over it. It featured a firing chamber beneath and a small gap of a few inches between barrel and brick vault leading to a chimney on top. L brackets were welded inside to take specially constructed baking pans. I really liked the detail of adding several inches of sand at the bottom of the barrel to hold some thermal mass. We created a nice earthen plaster to cover the oven. We had some really nice food out of this oven, and I was impressed by its efficiency and ease of use. I remembered this design later, when faced with creating an oven for a fuel-starved project in South Africa (more on that later). Editor’s note: find out more about barrel ovens….

I first was exposed to a barrel oven when I spent several months at Gaia Ecovillage in Argentina in 1998. This was an intriguing device: a 55 gallon barrel held in place by brick ends with a brick vault built over it. It featured a firing chamber beneath and a small gap of a few inches between barrel and brick vault leading to a chimney on top. L brackets were welded inside to take specially constructed baking pans. I really liked the detail of adding several inches of sand at the bottom of the barrel to hold some thermal mass. We created a nice earthen plaster to cover the oven. We had some really nice food out of this oven, and I was impressed by its efficiency and ease of use. I remembered this design later, when faced with creating an oven for a fuel-starved project in South Africa (more on that later). Editor’s note: find out more about barrel ovens….

In 2002 I was living in Sonoma County on an organic fruit orchard. I held a series of workshops there, and decided on building an outdoor kitchen. I realized that I wanted a real kitchen, with a sink, counters, stove and a place to sit. So, I designed it with all of these. We an oven base and seat base of gravel bags, which we then covered with cob. We built up the backs of the seats with cob. In the workshop was an amateur blacksmith, who offered to make an oven door for us. We cobbed in a sink, and the kettle part of a Weber grill, and made a counter by spanning cob columns with bamboo and cobbing over that. I used the amazing sand form method, and creating a cob layer, as well as an external layer of straw-clay (I thought insulation would be good). I had heard differ

In 2002 I was living in Sonoma County on an organic fruit orchard. I held a series of workshops there, and decided on building an outdoor kitchen. I realized that I wanted a real kitchen, with a sink, counters, stove and a place to sit. So, I designed it with all of these. We an oven base and seat base of gravel bags, which we then covered with cob. We built up the backs of the seats with cob. In the workshop was an amateur blacksmith, who offered to make an oven door for us. We cobbed in a sink, and the kettle part of a Weber grill, and made a counter by spanning cob columns with bamboo and cobbing over that. I used the amazing sand form method, and creating a cob layer, as well as an external layer of straw-clay (I thought insulation would be good). I had heard differ ent schools of thought about when you should take out the sand form: 1. Right away and 2. After a long time. Being the impatient sort, I went with #1. Oops. Wrong choice. The inner layer collapsed. Wahhh! But the external straw-clay layer stayed, and luckily was more clay than straw. So… we used it anyway. I ended up plastering the inside, and lived with having a bigger oven. I assume most of the straw has now burnt out, but it ended up working fine. A key thing I started to do with this oven was to eliminate the ash/coal removal process. I did this by loosely piling fired bricks inside the oven. The hot coals and ash would sift down between the bricks, and I would cook in cast iron pans right over the coals. I refuse to mess around with hot coals again. This ended up working really well, as it also raised the cooking vessels into the hotter part of the oven, while providing cooking heat from below and good radiant heat from the cob roof of the oven. While it looked great, and was convenient, I don’t think I will do a metal door again: it lets out too much heat.

ent schools of thought about when you should take out the sand form: 1. Right away and 2. After a long time. Being the impatient sort, I went with #1. Oops. Wrong choice. The inner layer collapsed. Wahhh! But the external straw-clay layer stayed, and luckily was more clay than straw. So… we used it anyway. I ended up plastering the inside, and lived with having a bigger oven. I assume most of the straw has now burnt out, but it ended up working fine. A key thing I started to do with this oven was to eliminate the ash/coal removal process. I did this by loosely piling fired bricks inside the oven. The hot coals and ash would sift down between the bricks, and I would cook in cast iron pans right over the coals. I refuse to mess around with hot coals again. This ended up working really well, as it also raised the cooking vessels into the hotter part of the oven, while providing cooking heat from below and good radiant heat from the cob roof of the oven. While it looked great, and was convenient, I don’t think I will do a metal door again: it lets out too much heat.

A couple of years later, I made another edition of the outdoor kitchen based with students from New College. Used all my lessons: counter height, sand form, insulating outer layer, Quebec-shape, nearby counters and seating and added a new twist: a pot boiler designed at the chimney hole.

I also held a workshop at my home, where we made an entire cob oven in a weekend. Phew!

South Africa called again in 2004, and I went over for a series of workshops and design sessions designing a children’s village in a rural town outside of Pretoria. I was asked to design an outdoor kitchen, and remembered the high efficiency oven I saw in Argentina. I created a design based on my memory, made some sketches, and when a colleague of mine went over, he built the oven as part of an outdoor kitchen and eating complex. From all reports it works great. I also designed a ground rocket stove for use with the cast iron cooking pots, but I never heard how that worked out.

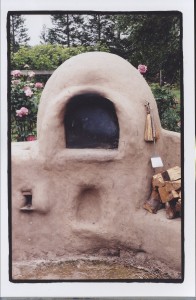

In 2007 and had the opportunity to design and build an outdoor pavilion and kitchen for a client in Healdsburg. I had a chance to do all sorts of cool natural building stuff on this project: super refined cob walls, roman style pebble floors, an outdoor sitting area, and… a cob oven. We decided to add a chimney, since this was a high fire danger area, and we didn’t want to have any sparks. I used all my tricks up to this point, adding an idea of using vermiculite instead of straw to make an insulating layer. And I had learned my lesson, and let this oven dry slooowwwwly. It turned out beautifully, and bakes well, too.

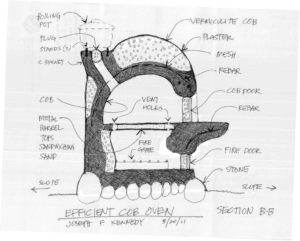

By this point, ho wever, I had become somewhat disenchanted by earth ovens as I had built them, no matter how much I love building and cooking in them. In fact I cringe now whenever I see another wood oven workshop being advertised. The main reason for my change of heart is that most earthen ovens are incredibly wasteful of wood and heat energy. I have so often seen an oven fired for hours just to cook a few pizzas, wasting wood, and sending carbon dioxide and particulate matter into the air. As someone who is trying to save resources, this seemed untenable. Then I heard about this mad scientist down in Los Angeles, Ray Cirino, who was coming up with a super-efficient cob oven concept. I knew I was onboard. After some back and forth on the coblist, I got enough ideas for my next effort, which is currently under construction at a high school in Sonoma County.

wever, I had become somewhat disenchanted by earth ovens as I had built them, no matter how much I love building and cooking in them. In fact I cringe now whenever I see another wood oven workshop being advertised. The main reason for my change of heart is that most earthen ovens are incredibly wasteful of wood and heat energy. I have so often seen an oven fired for hours just to cook a few pizzas, wasting wood, and sending carbon dioxide and particulate matter into the air. As someone who is trying to save resources, this seemed untenable. Then I heard about this mad scientist down in Los Angeles, Ray Cirino, who was coming up with a super-efficient cob oven concept. I knew I was onboard. After some back and forth on the coblist, I got enough ideas for my next effort, which is currently under construction at a high school in Sonoma County.

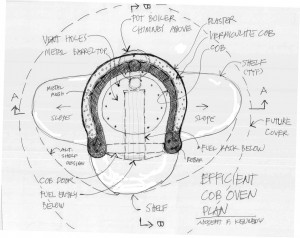

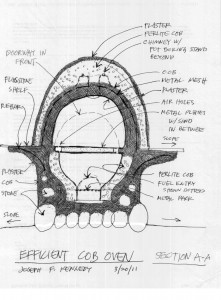

For this project I am putting together all my features into my ultimate oven. Counter height? Check. Vermiculite cob insulation? Check. Quebec shape? Check. Pot boiler chimney? Check. But, now, with the addition of a firing chamber beneath the oven, and a metal baking shelf, I hope to create an oven that can be used to cook with right away, is easier to regulate, and is much more efficient with wood use. Stay tuned. I will be sure to send more information as we complete the oven.

So that is my story to date. I hope you have enjoyed it.

Note from the Editor: It has been gratifying to see the attention that this guest article has received…. If you have a story about making ovens, heating your home, working with natural materials or even something else you want to share, let us know about your story so we can work together to get it published.

Hi, thanks for the diagrams. Super helpful. I’m new to this and been researching to build an outdoor bread oven. I have been intuitively wondering about a separate firing chamber under the dome chamber as not to worry about ashes polluting the dough. Would be real good if you’re able to post pictures and lessons learned from the actual experience with this project (assuming it has been completed). Thanks, again.

Hi was looking a this and was thinking how hot the oven gets,and how you monitor the temp

you can tell a lot by feel; thermometers (laser and analog) also work…

I live in Tanzania and am working on creating a prototype cob SOLAR oven. Because of de-forestation a new law has been passed and it is now illegal to sell firewood. This has made it very difficult for the people whose primary way of cooking is with firewood. We want to design something that can be replicated in the villages with local materials (aside from the glass and possibly the oven door. Any thoughts or ideas for us?

Interesting! My main comment would be to suggest thinking about a VERY insulative cob. Unlike a wood-fired cob oven where you are trying to store the heat in the mass and then bake…. you are trying to focus the sun’s energy directly into the food. I would recommend a mix of clayey soil and such things as rice hulls, wheat threshings, possible hollow straw or other reed material, etc. Also make your door low so all the heat doesn’t escape when you are reaching in to work with the food. Hope this helps!

I would request to kindly provide more information on Solar cum wood/ pine charcoal ovens too…i am doing research on migrated villagesof Himalayan foothills and need help.

Hi Joe,

Great story and I feel for you as you came to grips with the fuel efficiency of those earlier mass heat stoves you built.

From what I can gather in my more limited experience than yours Joe, I like you Joe like the idea of sand on the bottom of the Barrel Ovens but equally I think they have it wrong with their heat consuming mass on the other side of the air gap surrounding the inner barrel. Air is a poor transmitter of heat and the idea of first taking it out of the air stream and then feeding it back into the same air stream seems counter productive and certainly goes against the laws of thermodynamics for efficiency. I would have assumed it would be better to use an insulator on that side of the gap. I am willing to go as far as say fairly certain. The Firespeaking.com site seems nice but I have searched and have not produced any sort of industry methodology or any measurements at all on the effectiveness of their stoves. I am just a little sceptical due to their 1000 usd oven kit and their 18 usd e-book but I have not read or used their kit so I certainly could be wrong on both counts.

From about a years worth of research only, if I had to choose the best design and organization to go with for a family or small business user then Approvecho would be my own choice for substance over guess work. The Approvecho Rocket barrel ovens are hands down the most efficient bread ovens at 60 pounds of bread cooked on 10 pound of wood. Apprprovecho are a humanitarian organization and have had years of experience in research and measuring their results. They certainly can tell you why the gap around the barrel should be a certain distance and look at the two schools of thought in calculating the gap size.

Scott, Dr Tlud has or at least the Haiti Reconstruction International group has looked at Tluds combined with both stoves and Ovens

Ray

good resource here with easy to follow diagrams, etc; http://eosinternational.org/wp-content/uploads/2011/11/EOS-FEBO-Oven-Manua.pdf

Thanks so much for contributing this resource. A great pamphlet. We are also working on a book that describes a slightly different style of building this similar oven and goes more in depth into the process. Here’s the announcement for the upcoming Barrel Oven book. We will look to include this both in our online resources and in the printed book.

Thoroughly enjoyed your article…am I the only one here that wishes I had your lifestyle? Certainly your greatest reward is building for the greater good.

I’ve prepared several hundred lbs of clay and split another few hundred lbs of timber, ready to construct my next cob oven, and now you have me seriously questioning the efficiency (wasted heat, wood useage, etc.) of the type of oven I build, 36″ Pompeii.

I did however recently learn of ?? (someone help me with his name?) who suggests a “double chamber” oven with a chimney is considerably more efficient and emits far less smoke-if any at all-when used/designed correctly (i.e., slot at bottom of oven door is equivelant to area of chimney diameter). How this would apply to an oven built strictly for pizza, which is direct-fired, I do not know…it uses no door.

My thoughts are turning to a firebox beneath the hearth and a ceiling height slightly lower than the 14.5″ standard; theory being, lower ceiling would collect heat from hearth and radiate it more efficiently downward where it is needed. Next question is, will the food be missing out-so to speak-on receiving heat primarily from radiation and will conduction and convection loss be too great?

A possible inclusion/solution could be something I recently saw while searching online for soapstone slabs; open “slots” in the perimeter of the hearth which invariably allow for direct heat to enter the cooking chamber, think floor vents. A viable alternative?

I’m thinking of having a firebox under the hearth, as well. I am thinking of using firebricks for the hearth but leaving a large opening in the back of the hearth to allow heat to rise from the firebox up into the dome. This is a compromise between having the coals on the same surface as the food in one case, and the metal hearth in the other. I need to research more, but thought someone here may have input on my idea.

Also, I went to the masonry supply store today asking about clay mortar but they gave me a 5-pound bag of fire clay with a 45 lbs of spec mix and they said to just mix them together. is this ratio correct for building the dome? I don’t have access to clay soil in my area. Thanks

Thank you for all of the great ideas! I just became interested in Earth ovens and TLUD or biogass cook stoves. I wonder if anyone has combined the two? The TLUD (Top Lit Up Draft) stoves are super efficient and could possibly be used to heat an Earth oven from below. They burn all of the wood gasses that come out when biomasses are heated and one of the bi-products is Bio-char which is being used in gardening as a “condominium for microbes” plus it is used to sequester carbon.

Thanks again,

Scott

Which blog script does one use on the website. I’m interested as I wish to start my very own similar blog.

Here’s more information about this site, including what “blog” script we use.

My wife, Eva, and I have been working hard on a book in English about the Barrel Oven that you mention having seen at GAIA Ecovillage in Argentina. During my 7 years in Argentina, I saw many Barrel Ovens in use and also built several. Upon moving to the US, I realized that there wasn’t any information in English about this useful style of wood-fired oven which is why we have put effort towards publishing something about it. We currently have posted information about the Barrel Oven here and look forward to publishing the book very soon through Handprint Press so there will be more soon on this site! Looking forward to continuing these conversations!

Thanks for the story. Good writing, good reading! The plans for the efficient oven look great and I’m excited to see it in progress.

I’d recommend moving your re-bar up, closer towards the counter. With cob, like concrete, you have great compressive strength, but much less tensile strength, the reason straw is added in large amounts for overhangs for bookshelves. The re-bar looks to be pretty near the “neutral” plane which is the area that won’t stretch or compress much if a load (weight) is put near the outer edges of the counter. Below the neutral plane(arching lower side of the counter) will try to compress, while above the neutral plane (the flat upper side of the counter) will try to stretch to compensate for someone leaning/sitting on the counter or a heavy load (big pot of H2O) placed there. If the re-bar is moved closer to the top of the counter, it will help resist that tendency to stretch, and ultimately crack.

Better yet, you might use slip straw there and keep the extension less than 1 to 1, 45 deg angle out. The straw would give the firebox a little more insulation and probably have some benefit. Keeping the firebox hotter and bouncing that heat back into the oven, rather than letting it out when that lower part of the firebox is saturated with heat, as I’m guessing it will saturate much faster than the middle and top sections of the oven.

Just suggestions and thoughts. Appareantly you know what you’re doing with cob ovens. I’ve never built a single one, just done some reading on cob and studied some physics/structural engineering and am going solely on theory (we know how well that works out, haha)

Keenan

the part about the bricks being far enough apart that the coals fall thru. id love to know more details about that. and i would love to look at the drawings for this effecient cob oven you are doing but its very hard to read the scanned print. any chance to get a more definitive copy? thanks for your article i found it supper fun to read.

auggie

Thank you for sharing your experience ! We are planning on building a small indoors brick/clay wood fired oven- the base will be of firericks and the lower part of the vault whre we will lay on side firebricks creating a board. I really like the concept of the kettle chimney part. Is thi the main chimney while fired or just an alternative one so the fumes are getting out from the front door ?

Cheers,